Resumen

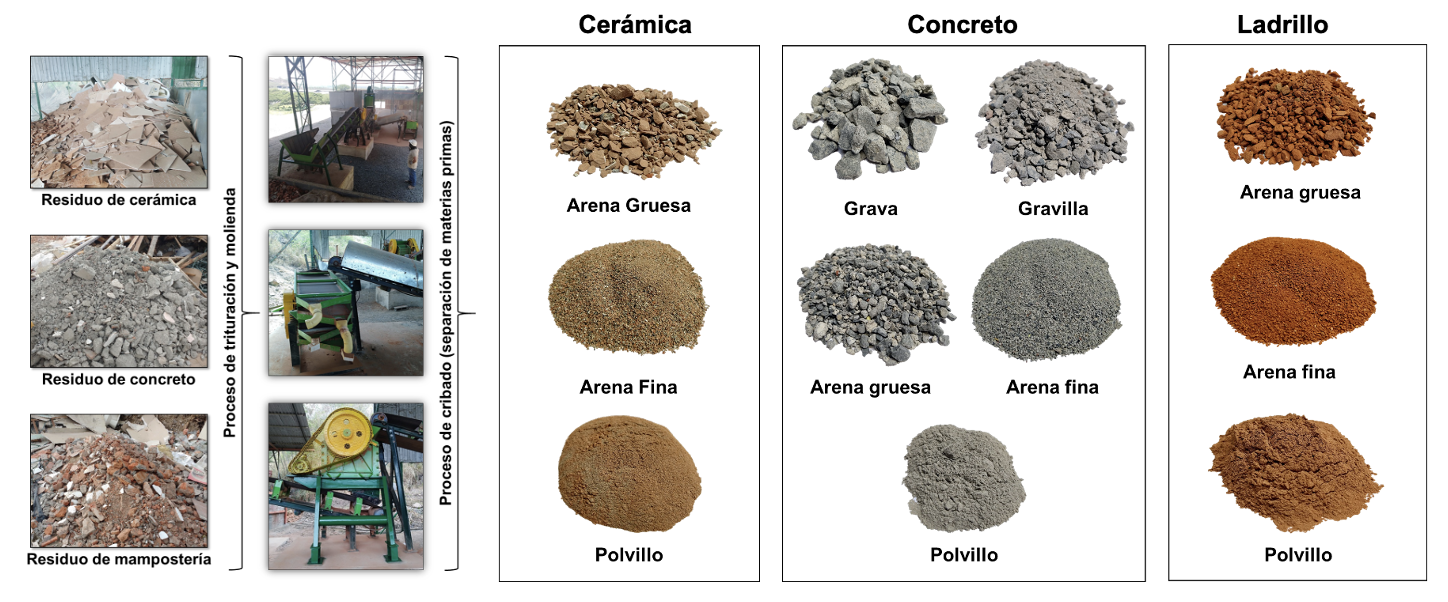

El cemento Portland (OPC) es el cementante comúnmente utilizado en la producción de concreto. Sin embargo, su uso se ha cuestionado por el excesivo consumo energético y de recursos naturales, y por las elevadas emisiones durante su proceso de producción. Por otra parte, el sector de la construcción también contribuye al impacto ambiental con la generación de residuos de construcción y demolición (RCD) que no están siendo aprovechados. Ello ha motivado el desarrollo de cementantes alternativos de menor huella de carbono y la reutilización de los RCD para dar cumplimiento a los Objetivos de Desarrollo Sostenible (ODS) y a los principios de economía circular. Se demuestra aquí la viabilidad de producir concretos de naturaleza híbrida activados alcalinamente a partir de la mezcla de polvos provenientes de la trituración de los RCD. Se emplearon dos tipos de activadores alcalinos, NaOH+Na2SiO3, y Na2SO4, con una proporción de OPC de 10 y 30 %, respectivamente. Para el aprovechamiento integral de los RCD, en las mezclas el 100 % de los agregados eran reciclados. Los concretos diseñados cumplieron las resistencias mecánicas requeridas por la norma sismo resistente NSR-10, lo que los clasifica como de tipo estructural. Además, su potencial de calentamiento global (PCG) fue hasta un 68 % inferior al de un concreto de igual especificación basado en OPC. Los concretos obtenidos se utilizaron en la producción de elementos prefabricados, tales como bloques macizos y bloques de perforación vertical y adoquines, que satisfacen las especificaciones requeridas en las normas técnicas colombianas.

Referencias

Adesina, A. & Rodrigue Kaze, C. (2021). Physico-mechanical and microstructural properties of sodium sulfate activated materials: A review. Construction and Building Materials, 295, 123668. https://doi.org/10.1016/j.conbuildmat.2021.123668.

Akhtar, A., Sarmah, A.K. (2018). Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. Journal Cleaner Production, 186, 262– 281. https://doi.org/10.1016/j.jclepro.2018.03.085.

Allahverdi, A. (2013). Use of construction and demolition waste (CDW) for alkali-activated or geopolymer cements. In F. Pacheco Torgal, V. Tam, J.A. Labrincha, Y. Ding y J. de Brito (Eds.), Handbook of recycled concrete and demolition waste, Woodhead Publishing Series.

Alsalman, A., Assi, L.N., Kareem, R.S., Carter, K., Ziehl, P. (2021). Energy and CO2 emission assessments of alkali-activated concrete and Ordinary Portland Cement concrete: A comparative analysis of different grades of concrete. Cleaner Environmental Systems, 3, 100047. https://doi.org/10.1016/j.cesys.2021.100047.

American Concrete Institute. (2019). ACI 318, Requisitos del código de construcción para concreto estructural. https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/51687637.

Amran, Y.H.M., Alyousef, R., Alabduljabbar, H., El-Zeadani, M. (2020). Clean production and properties of geopolymer concrete; A review. Journal of Cleaner Production, 251, 119679. doi:https://doi.org/10.1016/j.jclepro.2019.119679.

Caneda-Martínez, L., Monasterio, M., Moreno-Juez, J., Martínez-Ramírez, S., García, R., Frías, M. (2021). Behaviour and Properties of Eco-Cement Pastes Elaborated with Recycled Concrete Powder from Construction and Demolition Wastes. Materials, 14(5), 1299. https://doi.org/10.3390/ma14051299.

Coaffee, J. (2008). Risk, resilience, and environmentally sustainable cities. Energy Policy, 36(12), 4633-4638. https://doi.org/10.1016/j.enpol.2008.09.048.

CONAMA. (2002). Resolução CONAMA No 307 Estabelece diretrizes, critérios e procedimentos para a gestão dos resíduos da construção civil. https://cetesb.sp.gov.br/licenciamento/documentos/2002_Res_CONAMA_307.pdf.

CVC-Univalle. (2022). Convenio Interadministrativo 0146-2020, Cali, Colombia.

Dadsetan, S., Siad, H., Lachemi, M., Sahmaran, M. (2019). Construction and demolition waste in geopolymer concrete technology: a review. Magazine of Concrete Research, 71(23), 1232-1252. https://doi.org/10.1680/jmacr.18.00307.

Deloitte. (2015). Screening template for Construction and Demolition Waste management in The Netherlands.https://ec.europa.eu/environment/pdf/waste/studies/deliverables/CDW_Czech%20Republic_Factsheet_Final.pdf.

Deloitte. (2015). Screening template for Construction and Demolition Waste management in The Netherlands. https://ec.europa.eu/environment/pdf/waste/studies/deliverables/CDW_The%20Netherlands_Factsheet_Final.pdf.

Departamento Nacional de Planeación. (2016). Documento CONPES 3874, Política nacional para la gestión integral de residuos sólidos. https://colaboracion.dnp.gov.co/CDT/Conpes/Econ%C3%B3micos/3874.pdf

Deutsches Institut fur Normung E.V. (2017). DIN EN 4226-101/102. Recycled Aggregates for concrete in accordance with DIN EN 12620. https://global.ihs.com/doc_detail.cfm?document_name=DIN%204226%2D102&item_s_key=00728457

Djobo, J.N.Y., Tchakouté, H.K., Ranjbar, N., Elimbi, A., Tchadjié, L.N., Njopwouo, D. (2016).Gel Composition and Strength Properties of Alkali-Activated Oyster Shell-Volcanic Ash:Effect of Synthesis Conditions. Journal of American Ceramic Society, 99, 3159-3166. https://doi.org/10.1111/jace.14332

European Commission. (2016). Construction and demolition waste (CDW). https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en#overview

García-Lodeiro, I., Palomo, A., Fernández-Jiménez, A., Macphee, D.E. (2011). Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O–CaO– Al2O3–SiO2–H2O. Cement and Concrete Research, 41, 923–931. https://doi.org/10.1016/j.cemconres.2011.05.006.

García-Lodeiro, I., Maltseva, O., Palomo, A., Fernández-Jiménez, A. (2012). Hybrid alkaline cements. Part I: Fundamentals. Romanian Journal of Materials, 42(4), 330-335.

García-Lodeiro, I., Fernández-Jiménez, A., Palomo, A. (2013). Variation in hybrid cements over time. Alkaline activation of fly ash-portland cement blends. Cement and Concrete Research, 52, 112-122. https://doi.org/10.1016/j.cemconres.2013.03.022.

García-Lodeiro, I., Fernández-Jiménez, A., Palomo, A. (2018). Hybrid alkaline cements: Bentonite-OPC binders. Minerals, 8, 137. https://doi.org/10.3390/min8040137.

Gobierno de España. (2008). Real Decreto 105/2008 por el cual se regula la producción y gestión de los residuos de construcción y demolición. https://www.boe.es/buscar/act.php?id=BOE-A-2008-2486.

Gobierno de España. (2011). Ley 22/2011, Residuos y Suelos Contaminados. https://www.boe.es/buscar/pdf/2011/BOE-A-2011-13046-consolidado.pdf.

Habert, G., D’Espinose De Lacaillerie, J.B., Roussel, N. (2011). An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. Journal of Cleaner Production, 19(11), 1229–1238, https://doi.org/10.1016/j.jclepro.2011.03.012.

Huang, B., Wang, X., Kua, H., Geng, Y., Bleischwitz, R., Ren, J. (2018). Construction and demolition waste management in China through the 3R principle. Resources, Conservation and Recycling, 129, 36-44. https://doi.org/10.1016/j.resconrec.2017.09.029.

ICONTEC. (1997). NTC 4026, Unidades (bloques y ladrillos de concreto), para mampostería estructural. https://tienda.icontec.org/gp-ingenieria-civil-y-arquitectura-unidades-bloques-yladrillos-de-concreto-para-mamposteria-estructural-ntc4026-1997.html.

ICONTEC. (2018). NTC 2017, Adoquines de concreto para pavimentos. https://tienda.icontec.org/gp-adoquines-de-concreto-para-pavimentos-ntc2017-2018.html.

ICONTEC. (2021). NTC 6421, Agregados gruesos reciclados para uso en el concreto hidráulico.https://tienda.icontec.org/gp-agregados-gruesos-reciclados-para-uso-en-el-concretohidraulico-ntc6421-2021.html.

Kim Y.J., Choi, Y.W. (2012). Utilization of waste concrete powder as a substitution material for cement. Construction and Building Materials, 30, 500-504. https://doi.org/10.1016/j.conbuildmat.2011.11.042.

Komkova, A., Habert, G. (2023). Environmental impact assessment of alkali-activated materials: Examining impacts of variability in constituent production processes and transportation. Construction and Building Materials, 363, 129032. https://doi.org/10.1016/j.conbuildmat.2022.129032.

Komnitsas, K., Zaharaki, D., Vlachou, A., Bartzas, G., Galetakis, M. (2015). Effect of synthesis parameters on the quality of construction and demolition wastes (CDW) geopolymers. Advanced Powder Technology, 26(2), 368-376. https://doi.org/10.1016/j.apt.2014.11.012.

Ministerio de Ambiente y Desarrollo Sostenible - MADS. (2010). Reglamento Colombiano de Construcción Sismo-Resistente (NSR-10). https://nuevalegislacion.com/files/susc/cdj/conc/nsr_10.pdf.

MADS. (2017). Resolución No. 0472, Reglamento para la gestión integral de los residuos generados en las actividades de construcción y demolición - RCD. https://www.minambiente.gov.co/documento-normativa/resolucion-0472-de-2017/.

MADS. (2019). Estrategia Nacional de Economía Circular. https://economiacircular.minambiente.gov.co/index.php/lineas-de-accion/flujo-materiales-de-construccion/.

MADS. (2021). Resolución No. 1257, Por la cual se modifica la Resolución 0472 de 2017 sobre la gestión integral de los residuos de construcción y demolición – RCD y se adoptan otras disposiciones. https://www.minambiente.gov.co/documento-normativa/resolucion-1257-de-2021/.

Ministerio de Transporte. (2016). Code on Structural Concrete EHE-08, España. http://asidac.es/asidac-en/wp-content/uploads/2016/07/EHE-ENG.pdf.

Naciones Unidas. (2018, diciembre). Agenda 2030 y los Objetivos de Desarrollo Sostenible: una oportunidad para América Latina y el Caribe. https://repositorio.cepal.org/bitstream/handle/11362/40155/24/S1801141_es.pdf.

Ortiz, O., Castells, F., Sonnemann, G. (2009). Sustainability in the construction industry: A review of recent developments based on LCA. Construction and Building Materials, 23(1), 28–39. https://doi.org/10.1016/j.conbuildmat.2007.11.012.

Ouellet-Plamondon, C., Habert, G. (2015). Life cycle assessment (LCA) of alkali-activated cements and concretes. In F. Pacheco-Torgal, J.A. Labrincha, C. Leonelli, A. Palomo, P. Chindaprasirt (Eds), Handbook of Alkali-Activated Cements, Mortars and Concretes, Woodhead Publishing.

Ozcelikci, E., Kul, A., Gunal, M.F., Ozel, B.F., Yildirim, G., Ashour, A., Sahmaran, M. (2023). A comprehensive study on the compressive strength, durability-related parameters and microstructure of geopolymer mortars based on mixed construction and demolition waste. Journal of Cleaner Production, 396, 136522. https://doi.org/10.1016/j.jclepro.2023.136522.

Provis, J., van Deventer, J.S.J. (2009). Geopolymers: Structure, processing properties and industrial applications, Woodhead Publishing Ltda.

Rashad, A.M., Bai, Y., Basheer, P.A.M., Milestone, N.B., Collier, N.C. (2013). Hydration and properties of sodium sulfate activated slag. Cement and Concrete Composites, 37, 20-29. https://doi.org/10.1016/j.cemconcomp.2012.12.010.

Robayo-Salazar, R., Valencia-Saavedra, W., Mejía de Gutiérrez, R. (2022). Recycling of concrete, ceramic, and masonry waste via alkaline activation: Obtaining and characterization of hybrid cements. Journal of Building Engineering, 46, 103698. https://doi.org/10.1016/j.jobe.2021.103698.

Robayo-Salazar, R.A., Valencia-Saavedra, W. Mejía de Gutiérrez, R. (2020). Construction and Demolition Waste (CDW) Recycling — As Both Binder and Aggregates — In AlkaliActivated Materials: A Novel Re-Use Concept. Sustainability, 12, 5775. https://doi.org/10.3390/su12145775.

Shagñay, S., Bautista, A., Velasco, F., Torres-Carrasco, M. (2021). Hybrid cements: Towards their use as alternative and durable materials against wear. Construction and Building Materials, 312, 125397. https://doi.org/10.1016/j.conbuildmat.2021.125397.

Swiss Centre for Life Cycle Inventories. (2019). Ecoinvent OpenLCA database version 3.6. https://www.ecoinvent.org/database.html.

Tan, J., Cai, J., Li, J. (2022a). Recycling of unseparated construction and demolition waste (UCDW) through geopolymer technology. Construction and Building Materials, 341, 127771. https://doi.org/10.1016/j.conbuildmat.2022.127771.

Tan, J., Cizer, Ö., De Vlieger, J., Dan, H., Li, J. (2022b). Impacts of milling duration on construction and demolition waste (CDW) based precursor and resulting geopolymer: Reactivity, geopolymerization and sustainability. Resources, Conservation and Recycling, 184, 106433, https://doi.org/10.1016/j.resconrec.2022.106433.

Turner, L.K., Collins, F.G. (2013). Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Construction and Building Materials, 43, 125–130. https://doi.org/10.1016/j.conbuildmat.2013.01.023.

Valencia-Saavedra, W., Robayo-Salazar, R.A., Mejía de Gutiérrez, R. (2021). Alkali-Activated Hybrid Cements Based on Fly Ash and Construction and Demolition Wastes Using Sodium Sulfate and Sodium Carbonate. Molecules, 26(24), 7572. https://doi.org/10.3390/molecules26247572.

Yıldırım, G., Kul, A., Özçelikci, E., Sahmaran, M., Aldemir, A., Figueira, D., Ashour, A. (2021). Development of alkali-activated binders from recycled mixed masonry-originated waste. Journal of Building Engineering, 33, 101690. https://doi.org/10.1016/j.jobe.2020.101690.

Zaharaki, D., Galetakis, M., Komnitsas, K. (2016). Valorization of construction and demolition (C&D) and industrial wastes through alkali activation. Construction and Building Materials, 121, 686–693. https://doi.org/10.1016/j.conbuildmat.2016.06.051.

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Derechos de autor 2023 Revista de la Academia Colombiana de Ciencias Exactas, Físicas y Naturales