Abstract

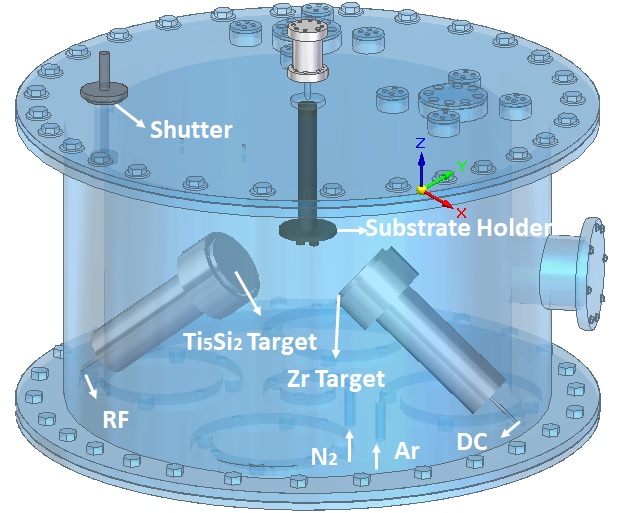

d Zr targets. The synthesis of the coatings was carried out by varying the discharge power in the Ti5 well as a variation in the deposit temperature at room temperature 130° and 260°C. The coatings were characterized by means of X-ray diffraction (XRD), evidencing the formation of the phase that belongs to the solid solution (Zr, Ti)N, scanning electron microscopy (SEM), UV-Vis spectroscopy and hardness and pin-on-disc tests. The thickness was measured through interferometry with values between 662 and 481nm for the deposited coatings. According to the failure mechanism in the scratch test, the best results were obtained with a power of 170W and 260°C with a cohesive failure Lc1 = 2.1N and an adhesive failure Lc2 = 4.7N.

Keywords

References

Abadias, G., Daniliuk, A. Y., Solodukhin, I. A., Uglov, V. V., & Zlotsky, S. V. (2018). Thermal stability of TiZrAlN and TiZrSiN films formed by reactive magnetron sputtering. InorganicMaterials: Applied Research. 9 (3): 418-426. doi.org/10.1134/S2075113318030024

Abadias, G., Koutsokeras, L. E., Dub, S. N., Tolmachova, G. N., Debelle, A., Sauvage, T., & Villechaise, P. (2010). Reactive magnetron cosputtering of hard and conductive ternary nitride thin films: Ti–Zr–N and Ti–Ta–N. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films. 28 (4): 541-551. doi.org/10.1116/1.3426296

Abrikosov, I. A., Knutsson, A., Alling, B., Tasnádi, F., Lind, H., Hultman, L., & Odén, M. (2011). Phase stability and elasticity of TiAlN. Materials. 4 (9): 1599-1618. doi.org/10.3390/ma4091599.

Attari, V., Cruzado, A., & Arroyave, R. (2019). Exploration of the microstructure space in TiAlZrN ultra-hard nanostructured coatings. Acta Materialia. doi.org/10.1016/j.actamat.2019.05.047.

Baturina, O. A., Epshteyn, A., Purdy, A., Simpkins, B., Forcherio, G. T., & Govorov, A. O. (2019). Comparison of Photocatalytic Activities of TiN and Zrn Nanoparticles Incorporated into TiO2 matrix Under Visible Excitation. In Meeting Abstracts (No. 45, pp. 2072-2072). The Electrochemical Society.

Bendavid, A., Martin, P. J., Kinder, T. J., & Preston, E. W. (2003). Properties of Ti1-xSixNy films deposited by concurrent cathodic arc evaporation and magnetron sputtering. Surf. Coat. Technol, 163-164. doi.org/10.1016/S0257-8972(02)00491-7.

Bisbal, R., Dávila, P., Gomez, F., Camero, S., Pérez, M., & González, G. (2012). Efecto del Ta en la aleación Ti-6Al-4V tratada térmicamente. Revista de la Facultad de Ingeniería Universidad Central de Venezuela, 27 (4): 83-94.

Cardenas Flechas, L. J. (2018). Resistencia a la corrosión de recubrimientos nanoestructurados de Ti-Zr-Si-N. Ingeniería Mecánica.Universidad Nacional de Colombia. Retrieved from: https://repositorio.unal.edu.co/handle/unal/69879.

Cardenas, J., Leon, J., & Olaya, J. J. (2019). Synthesis and high-temperature corrosion resistance of Ti-Zr-Si-N coatings deposited by means of sputtering. Corrosion Engineering, Science and Technology, 54 (3): 233-240. doi.org/10.1080/1478422X.2019.1573498.

Cardenas, L. J. C., Barahona, E. T., Salamanca, M. L. P., Medina, J. X. L., & Florez, J. J. O. (2018). Evaluación de la resistencia a la oxidación de peliculas de Ti-Zr-Si-N producidas por cosputtering. Bistua Revista de la facultad de ciencias básicas. 15 (2). doi. org/10.24054/01204211.v2.n2.2017.2889.

Cardenas L., Raba, A. M., Barba-Ortega, J., Moreno, L. C., & Joya, M. R. (2021). Effect of Calcination Temperature on the Behavior of the Agglomerated Co3O4 Nanoparticles Obtained Through the Sol–Gel Method. Journal of Inorganic and Organometallic Polymers and Materials. 31 (1): 121-128. doi.org/10.1007/s10904-020-01685-5

Cardenas-Flechas, L. J., Raba, A. M., & Rincón-Joya, M. (2020). Synthesis and evaluation of nickel doped Co3O4 produced through hydrothermal technique. Dyna. 87 (213): 184-191. doi. org/10.15446/dyna.v87n213.84410

Ding, X. Z., Tan, A. L. K., Zeng, X. T., Wang, C., Yue, T., & Sun, C. Q. (2008). Corrosion resistance of CrAlN and TiAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films. 516 (16): 5716-5720. doi.org/10.1016/j.tsf.2007.07.069

Escobar, D., Ospina, R., Gómez, A. G., & Restrepo-Parra, E. (2015). Microstructure, residual stress and hardness study of nanocrystalline titanium–zirconium nitride thin films. Ceramics International. 41 (1): 947-952. doi.org/10.1016/j.ceramint.2014.09.012

Georgson, M., Roos, A., & Ribbing, C. G. (1991). The influence of preparation conditions on the optical properties of titanium nitride based solar control films. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films. 9 (4): 2191-2195. doi.org/10.1116/1.577249.

Guler, U., Boltasseva, A., & Shalaev, V. M. (2014). Refractory plasmonics. Science. 344 (6181): 263-264. doi: 10.1126/science.1252722

Huang, J. H., Ho, C. H., & Yu, G. P. (2007). Effect of nitrogen flow rate on the structure and mechanical properties of ZrN thin films on Si (1 0 0) and stainless steel substrates. Materials chemistry and physics. 102 (1): 31-38. doi.org/10.1016/j.matchemphys.2006.10.007

Kameneva, A., & Kichigin, V. (2019). Corrosion, wear, and friction behavior of a number of multilayer two-, three-and multicomponent nitride coatings on different substrates, depending on the phase and elemental composition gradient. Applied Surface Science. doi.org/10.1016/j.apsusc.2019.05.331

Kiryukhantsev-Korneev, F. V., Shirmanov, N. A., Sheveiko, A. N., Levashov, E. A., Petrzhik, M. I., & Shtanskii, D. V. (2010). Nanostructural wear-resistant coatings produced on metalcutting tools by electric-arc evaporation and magnetronic sputtering. Russian Engineering Research. 30 (9): 910-920. https://doi.org/10.3103/S1068798X10090133

Klamchuen, A., Suzuki, M., Nagashima, K., Yoshida, H., Kanai, M., Zhuge, F., & Kawai, T. (2015). Rational concept for designing vapor–liquid–solid growth of single crystalline metal oxide nanowires. Nano letters. 15 (10): 6406-6412. doi.org/10.1021/acs.nanolett.5b01604

Köpf, A., Keckes, J., Todt, J., Pitonak, R., & Weissenbacher, R. (2017). Nanostructured coatings for tooling applications. International Journal of Refractory Metals and Hard Materials. 62:219-224. doi.org/10.1016/j.ijrmhm.2016.06.017

Lawal, J., Kiryukhantsev-Korneev, P., Matthews, A., & Leyland, A. (2017). Mechanical properties and abrasive wear behaviour of Al-based PVD amorphous/nanostructured coatings. Surface and Coatings Technology. 310: 59-69. doi.org/10.1016/j.surfcoat.2016.12.031

Lin, Y. W., Huang, J. H., Yu, G. P., Hsiao, C. N., & Chen, F. Z. (2015). Influence of ion bombardment on structure and properties of TiZrN thin film. Applied Surface Science. 354: 155-160. https://doi.org/10.1016/j.apsusc.2015.02.190

Ma, S. L., Ma, D. Y., Guo, Y., Xu, B., Wu, G. Z., Xu, K. W., & Chu, P. K. (2007). Synthesis and characterization of super hard, self-lubricating Ti–Si–C–N nanocomposite coatings. Acta Materialia. 55 (18): 6350-6355. doi.org/10.1016/j.actamat.2007.07.046

Macias, H. A., Yate, L., Coy, L. E., Aperador, W., & Olaya, J. J. (2019). Influence of Si-addition on wear and oxidation resistance of TiWSixN thin films. Ceramics International. 45 (14): 17363-17375. doi.org/10.1016/j.ceramint.2019.05.295

Mikula, M., Roch, T., Plašienka, D., Satrapinskyy, L., Švec Sr, P., Vlčková, D., & Kúš, P. (2014). Thermal stability and structural evolution of quaternary Ti–Ta–B–N coatings. Surface and Coatings Technology. 259: 698-706. doi.org/10.1016/j.surfcoat.2014.10.009

Miletić, A., Panjan, P., Škorić, B., Čekada, M., Dražič, G., & Kovač, J. (2014). Microstructure and mechanical properties of nanostructured Ti–Al–Si–N coatings deposited by magnetron sputtering. Surface and Coatings Technology. 241: 105-111. doi.org/10.1016/j.surfcoat.2013.10.050

Moshtaghioun, B. M., Gómez-García, D., & Domínguez-Rodríguez, A. (2018). Spark plasma sintering of titanium nitride in nitrogen: Does it affect the sinterability and the mechanical properties. Journal of the European Ceramic Society. 38 (4): 1190-1196. doi.org/10.1016/j.jeurceramsoc.2017.12.029

Nakayama, H., & Ozaki, K. (2015). Effect of mechanical milling of elemental powders on interface formation in TiN–Ni cermets prepared by pulsed current sintering. International Journal of Refractory Metals and Hard Materials. 51: 309-314. doi.org/10.1016/j.ijrmhm.2015.05.007

Olaya, J. J., Capote, G., & Marulanda. (2015). Producción, caracterizaciòn y aplicaciones de recubrimientos producidos por plasma. Universidad Nacional de Colombia. 1ra ed.

Parra JP, Piamba OE, Olaya JJ. (2015). Resistencia a la corrosión a alta temperatura en películas delgadas de Bix Tiy Oz producidas por sputtering R. F. Revista Latinoamericana de Metalurgia y Materiales. 36: 2-8.

Phaengam, W., Horprathum, M., Chananonnawathorn, C., Lertvanithphol, T., Samransuksamer, B., Songsiriritthigul, P., & Chaiyakun, S. (2019). Oblique angle deposition of nanocolumnar TiZrN films via reactive magnetron co-sputtering technique: The influence of the Zr target powers. Current Applied Physics. 19 (8): 894-901. doi.org/10.1016/j.cap.2019.05.002

Pogrebnjak, A. D., Shpak, A. P., Beresnev, V. M., Kolesnikov, D. A., Kunitskii, Y. A., Sobol, O. V., ... & Demyanenko, A. A. (2012). Effect of thermal annealing in vacuum and in air on nanograin sizes in hard and superhard coatings Zr–Ti–Si–N. Journal of Nanoscience and Nanotechnology. 12 (12): 9213-9219. doi.org/10.1166/jnn.2012.6777

Rizzo, A., Signore, M. A., Penza, M., Tagliente, M. A., De Riccardis, F., & Serra, E. (2006). RF sputtering deposition of alternate iN/ZrN multilayer hard coatings. Thin Solid Films. 515 (2): 500-504. doi.org/10.1016/j.tsf.2005.12.279

Romero, E. C., Osorio, J. C., Soto, R. T., Macías, A. H., & Botero, M. G. (2019). Microstructure, mechanical and tribological performance of nanostructured TiAlTaN-(TiAlN/TaN) n coatings: Understanding the effect of quaternary/multilayer volume fraction. Surface and Coatings Technology. 377: 124875. doi.org/10.1016/j.surfcoat.2019.07.086

Saladukhin, I. A., Abadias, G., Michel, A., Uglov, V. V., Zlotski, S. V., Dub, S. N., & Tolmachova, G. N. (2015). Structure and hardness of quaternary TiZrSiN thin films deposited by reactive magnetron co-sputtering. Thin Solid Films. 581: 25-31. doi.org/10.1016/j.tsf.2014.11.020

Pogrebnyak, A. D., & Beresnev, V. M. (2011). Effect of the preparation conditions on the phase composition, structure, and mechanical characteristics of vacuum-Arc Zr-Ti-Si-N coatings. The Physics of Metals and Metallography. 112 (2): 188. doi.org/10.1134/S0031918X11020268

Uglov, V. V., Abadias, G., Zlotski, S. V., Saladukhin, I. A., Skuratov, V. A., Leshkevich, S. S., & Petrovich, S. (2015). Thermal stability of nanostructured TiZrSiN thin films subjected to helium ion irradiation. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 354: 264-268. doi.org/10.1016/j.nimb.2014.12.043

Vanegas, H. S., Alfonso, J. E., & Olaya, J. J. (2019). Effect of Si content on functional behavior of nanostructured coatings of Zr–Si–N. Materials Research Express. 6 (11): 115076.

Veszelei, M., Andersson, K., Ribbing, C. G., Järrendahl, K., & Arwin, H. (1994). Optical constants and Drude analysis of sputtered zirconium nitride films. Applied optics. 33 (10): 1993-2001. doi.org/10.1364/AO.33.001993

Yalamanchili, K., Forsén, R., Jiménez-Piqué, E., Jöesaar, M. J., Roa, J. J., Ghafoor, N., & Odén, M. (2014). Structure, deformation and fracture of arc evaporated Zr–Si–N hard films. Surface and Coatings Technology. 258: 1100-1107. 10.1016/j.surfcoat.2014.07.024

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Copyright (c) 2021 Revista de la Academia Colombiana de Ciencias Exactas, Físicas y Naturales