Resumen

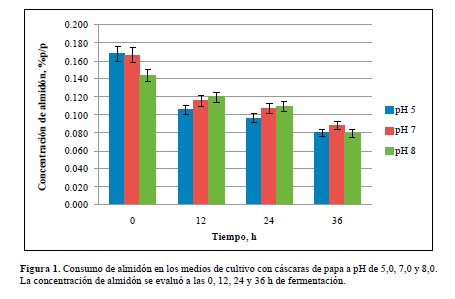

Los residuos agroindustriales de bajo costo, fácil acceso y contenido considerable de almidón pueden aprovecharse como sustratos para la producción de amilasas. En el presente estudio se evaluó la producción de amilasas con la cepa Bacillus amyloliquefaciens (aislamiento A16) en medios de cultivo ajustados a diferentes pH y preparados a partir de cáscaras de papa con 1,30 % de partes por volumen (p/v) de almidón. Los medios fueron incubados durante 36 horas a 37 °C y se tomaron muestras cada 12 horas para cuantificar mediante espectrofotometría el almidón residual revelándolo con solución de Lugol para obtener extractos enzimáticos crudos en los que se determinó la actividad amilolítica. La actividad de las amilasas producidas en sustratos preparados con cáscaras de papa se compararon con las actividades amilolíticas producidas en caldo de almidón al 1 %, sustrato que sirvió de control positivo. La mayor actividad de las amilasas producidas en medios con cáscaras de papa fue de 44,2 U/mL a las 36 horas de fermentación a un pH de 5,0, en tanto que la actividad enzimática en caldo de almidón al 1 % fue de 64,8 U/mL.

Referencias

Abd-Elhalem, B., El-Sawy, M., Gamal, R., Abou-Taleb, K. (2015). Production of amylases from Bacillus amyloliquefaciens under submerged fermentation using some agro-industrial yproducts. Annals of Agricultural Sciences. 60 (2): 193-202.

Bertoft, E. (2017). Understanding Starch Structure: Recent Progress. Agronomy. 7 (56): 1-29.

Bryjak, J. (2003). Glucoamylase, a-amylase and b-amylase immobilization on acrylic carriers. Biochemical Engineering Journal. 16: 347-355.

Buitrago, S., Sánchez, E., Guerrero, H. (2014). Aislamiento de microorganismos amilolíticos, celulolíticos y lignolíticos a partir del suelo de humedales de Bogotá. Revista SENNOVA. 1(1): 148-155.

Dutta, P., Deb, A., Majumdar, S. (2016). Optimization of the Medium for the Production of Extracellular Amylase by the Pseudomonas stutzeri ISL B5 Isolated from Municipal Solid Waste. International journal of microbiology, 2016, 4950743. https://doi.org/10.1155/2016/4950743

El Enhasy, H. (2007). Bioprocess development for the production of alpha amylase by Bacillus amyloliquefaciens in batch and fed-batch cultures. Research Journal of Microbiology. 2 (7):560-568.

El-Fallal, A., Abou, M., El-Sayed, A., Omar, N. (2012). Starch and Microbial α-Amylases: From Concepts to Biotechnological Applications. En C. Chang, Carbohydrates - Comprehensive Studies on Glycobiology and Glycotechnology (p. 459-488). IntechOpen.

Englyst, K., Hudson, J., Englyst, N. (2006). Starch Analysis in Food. En M. Meyers, Encyclopedia of Analytical Chemistry (p. 4246-4262). John Wiley & Sons Ltd. Accedido entre agosto y septiembre de 2019. doi:10.1002/9780470027318.a1029

Gerena Baron, F. (2013). Obtención de jarabes azucarados a partir de la hidrólisis química de residuos de cáscaras de naranja (citrus sinensis l var valencia) y papa (solanum tuberosum) variedad diacol capiro (r-12) para ser empleados como edulcorantes en la industria de alimentos. Repositorio Institucional UNAD. Fecha de consulta: 15 de agosto de 2019. Disponible en: https://repository.unad.edu.co/handle/10596/1528

Haq, I., Ashraf, H., Iqbal, J., Qadeer, M.A. (2003). Production of alpha amylase by Bacillus licheniformis using an economical medium. Journal Bioresource Technology. 87: 57-61.

Jadhav, S., Kataria, P., Bhise, K., Chougule, S. (2013). Amylase Production from Potato and Banana Peel Waste. International Journal of Current Microbiology and Applied Sciences. 2 (11): 410-414.

Karnwal, A. & Nigam, V. (2013). Production of amylase enzyme by isolated microorganisms and its application. International Journal of Pharmacy & Bio-Sciences. 3: 354-360.

Khalid-Bin-Ferdaus, K., Hossain M, F., Mansur, S., Sajib, S., Miah, M., Faisal, M., Reza, M. (2018). Commercial production of alpha amylase enzyme for potential use in the textile industries in Bangladesh. International Journal of Biosciences. 13 (4): 149-157.

Liang, S. & McDonald, A. (2014). Chemical and Thermal Characterization of Potato Peel Waste and Its Fermentation Residue as Potential Resources for Biofuel and Bioproducts Production. Journal of Agricultural and Food Chemistry. 62: 8421-8429.

Lizarazo, S., Hurtado, G., Rodríguez, L. (2015). Physicochemical and morphological characterization of potato starch (Solanum tuberosum L.) as raw material for the purpose of obtaining bioethanol. Agronomía Colombiana. 33 (2): 244-252.

Londoño-Posso, D. (2013). Validación del método de determinación de calcio y magnesio por espectroscopia de absorción atómica de llama para el laboratorio de Análisis de Aguas y Alimentos de la Universidad Tecnológica de Pereira. Repositorio UTP. Fecha de consulta: 15 agosto de 2019. Disponible en: http://repositorio.utp.edu.co/dspace/handle/11059/3406

Magallanes-Cruz, P., Flores-Silva, P., Bello-Pérez, L. (2017). Starch Structure Influences Its Digestibility: A Review. Journal of Food Science. 82 (9): 2016-2023.

Masson, L. (1994). Análisis proximal de calcio y fosforo en harinas de pescado. Fecha de consulta: agosto y septiembre de 2019. Disponible en: http://www.fao.org/3/ab482s/AB482S02.htm

Nigam, P. & Singh, D. (1995). Enzyme and microbial systems involved in starch processing. Enzyme Microbial Technology. 17 (9): 770-778.

Obi, N., Okezie, O., Ezugwu, A. (2019). Amylase Production by Solid State Fermentation of Agroindustrial Wastes Using Bacillus species. European Journal of Nutrition & Food Safety. 4: 408-414.

Olanbiwoninu, A. & Fasiku, S. (2015). Production of bacterial amylases and cellulases using sweet potato (Ipomoea batatas (L.) Lam.) peels. African Journal of Biochemistry Research. 9 (9):104-109.

Ortiz, I., Álvarez, V., Cervantes, G., Valenzuela, L., Potisek, M., Chávez, J. (2015). Concentración de almidón y proteínas solubles en tubérculos de Caladium bicolor en diferentes etapas fenológicas. Revista Mexicana de Ciencias Agrícolas. 6 (3): 483-494.

Pedroza, A. & Matiz, A. (2007). Aislamiento y selección de microorganismos productores de amilasas y celulasas . En A. Pedroza, A. Matiz, B. Quevedo, & A. Aguirre, Manual de introducción a la biotecnología (p. 118). Bogotá, Colombia: Pontificia Universidad Javeriana.

Peñaranda, L., Montenegro, S., Giraldo, P. (2017). Aprovechamiento de residuos agroindustriales en Colombia. Revista de Investigación Agraria y Ambiental. 8 (2): 141-150.

Quintero, M., Montoya, O., Gutiérrez, P. (2010). Purificación y caracterización de una αamilasa producida por la cepa nativa Bacillus sp. BM1. Dyna. 77 (162): 31-38.

Robyt, J. (1984). Enzymes in the hydrolysis and synthesis of starch. En R. Whistler, J. Bemiller, & E. Paschall, Starch: Chemistry and Technology (p. 87-123). London: Academic Press.

Romo, J., Torres, M., Orozco, F. (2019). Economical substrates for biotechnological production of lactic acid 83 - Biotechnological valorization of agro industrial and household wastes for lactic acid production. Revista Colombiana de Biotecnología. 21 (1): 83 - 97.

Sepelev, I. & Galoburda, R. (2015). Industrial potato peel waste application in food production: a review. Research for rural development. 1: 130-136.

Smerilli, M., Neureiter, M., Wurz, S., Haas, C., Frühauf, S., Fuchs, W. (2015). Direct fermentation of potato starch and potato residues to lactic acid by Geobacillus stearothermophilus under non-sterile conditions. Journal of Chemical Technology & Biotechnology. 90: 648-657.

Turner, P., Mamo, G., Karlsson, E. (2007). Potential and utilization of thermophiles and thermostable enzymes in biorefining. Microbial Cell Factories. 6 (9): 1-23.

Yildirim-Akatin, M. (2019). An Overview of Amylase Production by Solid State Fermantation (SSF) since 2010. Journal of Technical Sciences. 9 (1): 1-7.

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-SinDerivadas 4.0.

Derechos de autor 2020 Revista de la Academia Colombiana de Ciencias Exactas, Físicas y Naturales